STL Models: Why Engineers and Manufactures Love Them

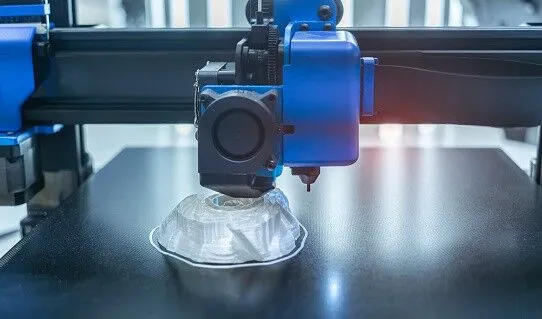

Everyone knows that 3D printers are the newest way to quickly make parts at low costs and fast turnarounds, but that’s only possible with the right file types. In this guide, we’re going to introduce STL models. We’ll explain why they’re great, why engineers love them, and why manufacturers highly prefer them.

What Is an STL Model?

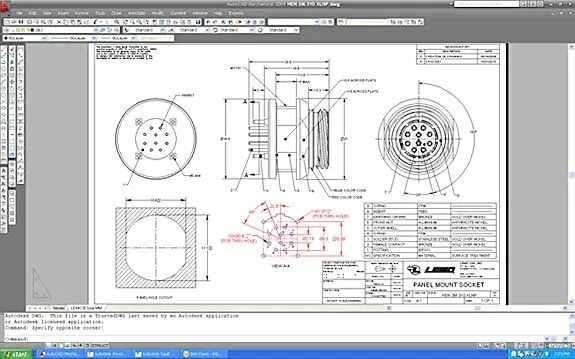

The name STL stands for stereolithography, Standard Triangle Language, or Standard Tessellation Language. All three of these acronyms sum up exactly what the file is: a collection of triangles that make a solid part.

In CAD, an STL model always starts as a solid, 3D model. There’s no way to create an STL model from scratch, since the model itself doesn’t have any volume. That’s right, an STL file just shows the external makeup of a part without any internal solids, also called a “mesh model”.

Back in the late 70s, STL files were created simply as a way to 3D print a model, and that’s the primary function of an STL model to this day. That’s why you don’t need any internal data, the 3D printer only cares about the external shape and the inside is created by a secondary processor (called a slicing software, on the side of the 3D printing company).

Some CAD programs will let you open STL models, but none of the commercial CAD programs can reliably let you adjust an STL file.

Instead, you would need to adjust the original 3D model and save it as an STL file.

Why Engineers Love STL Models

As an engineer, you might not fully understand how great STL models are, yet. In this section, we’ll outline some reasons why you should love this model type.

They’re Lightweight (Easy to Share)

STL files are actually just strings of text that you can open on a Notebook or word-processing app. Typically these files are just a few KB, which means that they’re small enough to send via email. They’re so small you can attach hundreds on the same email and you still won’t hit the size limit.

If you’re sharing these files internally, they can be stored on a simple flash drive or a small server without any issues.

Compare this to a typical 3D model saved in SolidWorks. The SLDPRT is likely going to be multiple MB or even GB if you’re working with a large SLDASM. Just a few models will be too large to share via email, so you’ll have to get creative about how you’ll share the parts.

They Import Directly into a Slicer

Every 3D printing slicer on the market allows the user to directly import STL files. The 3D printing company (or you) can then use the slicer software to optimize the print, set up all the parameters, and create G-code that will be loaded into the 3D printer.

Slicers can’t accept solid models from any CAD program, they strictly work with STL files. Why? The slicer software is reading the strings of text, translating them into a visual part, and loading in data that will ultimately tell the 3D printer what it needs to do in order to make this part.

This only works because STL files are so lightweight and minimal. Doing the same process on a physical 3D model would take way too much processing power and time.

STL Models are Fast to Make

In the time it takes you to read this sentence, you could make an STL model from scratch. It’s really that fast. In most CAD programs, you would use the “export” function on your 3D model, and save the file type as “.STL”.

Of course, the modeling is going to take some time, but physically converting the part only takes a few seconds.

This also means that you can revise parts and save multiple different STL files in very little time. This is ideal for people who want to prototype with different options or try certain configurations on their print to see what works best.

It’s a Universal Model Type

One of the most annoying parts of 3D modeling is trying to convert all your files into a similar model type. If you get a model from Inventor and SolidWorks but you’re working with Siemens NX, you’ll spend a lot of time messing around with import and export parameters before you get it right.

Even then, you’re left with models that don’t have the source data like material type, surface finish, and any dimension work that was done in the model. It’s frustrating.

With STL files, you don’t have to worry about this. An .STL file can be opened on any consumer-grade CAD program on the market, even free options like SketchUp. You can open the same .STL file on a dozen different programs and the part will look identical.

This is an example of a universal model, something you don’t see often in engineering.

They Allow You to Visualize a 3D Print

Another benefit is that you can open an STL file and see a visualization of what the part will look like. The STL can open in your CAD program or even Microsoft Paint 3D, which is crazy to think about. Once opened, you’ll see a scaled model of the part that you can move around and inspect.

When does this come in handy? If a peer sends you an STL model for 3D printing, you can first open it and make sure you understand the design before the printing process begins.

An STL file can also be opened very quickly, allowing you to double-check that you’re sending the right file before sending the message to your 3D printing shop.

Why Manufacturers Love STL Models

The benefits of STL models don’t stop with engineers. After you send the part to a manufacturer, they have a lot of things to love about the same model.

There Is No Room for Error

When a manufacturer works with 3D CAD models, they need to understand how that CAD program works. They also need to understand how to avoid messing up the file and ruining the model. There’s a lot of room for error with traditional 3D CAD models.

With STLs, you can’t adjust the model or ruin it at all. It’s simply a way to set up a print. If a 3D printing shop wanted to change the STL, it would take a lot of effort and won’t be done by accident.

This means that manufacturers can create the exact part you’re looking for.

Allows for Immediate 3D Printing

An STL file can be converted into G-code within a few minutes. Of course, G-code is the program that tells the 3D printing machine exactly what to do. With a slicing software, the manufacturer can prepare the STL model for 3D printing with very little effort.

If they were to convert a 3D model into a 3D-printable part, there would be a few more steps that would need to be done.

They Are Used as Reference After Printing Is Done

After the manufacturer physically prints the part, they can look at the STL model on their computer as a reference. This will ensure that the 3D printing process was successful.

Some higher-tech 3D printers even come with a screen that shows the STL file visualized on the printing bed of the 3D printer. Again, this is a way to ensure the right thing is being made.

Conclusion

STL models are a great way to send your part for 3D printing with much less stress and fewer potential errors. If you need help making professional-grade STL models, reach out to our team at CAD/CAM Services. We’re a full-service drafting team with 3D printing experts on-staff that can handle your drafting and engineering needs. Get a free quote today.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...