Blogs

Discover the latest CAD, 3D modeling, scanning, and more updates. Dive into our articles and stay informed to enhance your expertise in the field.

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...

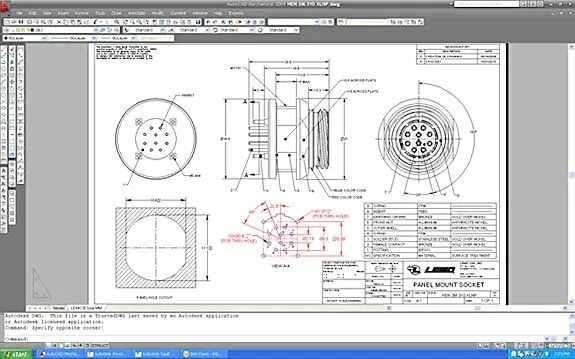

What is a CAD translation, and how does that differ from Raster to Vector conversion? Raster to vector conversion means taking a scanned raster file and changing it to a vector file. However, a CAD translation means taking a vector file that is in one format, usable...

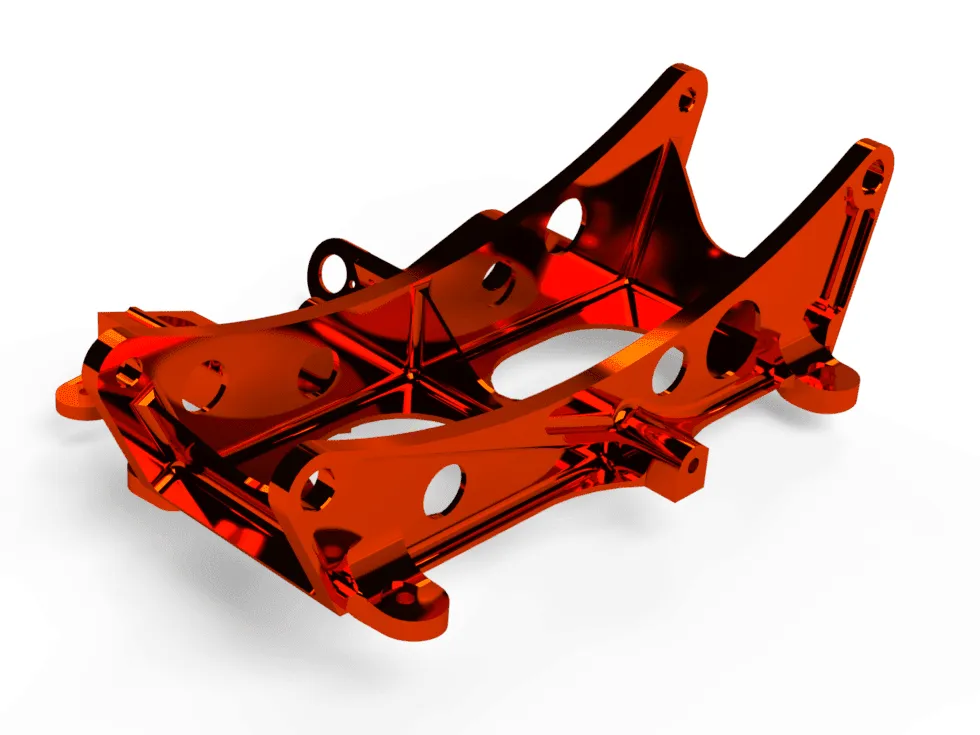

Take a Look at Our Case Studies! When it comes to understanding the workings of the CATIA Models Library, it is important to understand that the archives contain the data for many physical objectsIf we look at CATIA from its inception, then we can easily see that the...