What Is CAD / CAM?

What Is CAD / CAM?

By definition, CAD /CAM is an acronym standing for Computer Aided Design/Computer Aided Manufacturing. By implication, CAD / CAM controls both the design phase of a product and the manufacturing process. This is true because the CAD program that is used to design the product can also be used to control the CNC machines that are used to manufacture the product.

The CAD / CAM Process

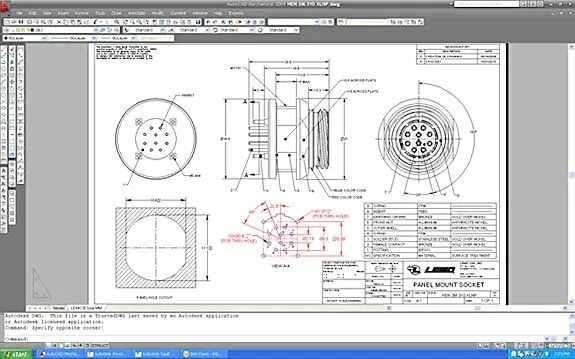

Once the product idea is conceived, it falls to the design engineer to generate design drawings. This design phase uses a CAD software, such as AutoCAD ®, which enables the designer to create accurate 2D drawings and realistic 3D images of the product. This automated process takes away much of the guesswork involved in designing a new product by enabling visualization of the working parts of the product and ensuring that they fit together and work as planned before manufacturing begins.

Once the design has been vetted via 3D visualizations, the CAM part of the process takes over. CAM automates the system of producing finished products by using computer controlled production machines. In this way, CAD and CAM work together digitally to compose a reliable set of fabrication instructions for the machines.

This is an example of a procedure commonly followed in CAD / CAM:

- The product idea is generated

- 2D CAD drawings based on engineering inputs, customer requirement, and product necessities are created

- A 3D digital model is generated from the 2D drawings using the 3D modeling application of the CAD software.

- The 3D model is analyzed by testing use virtually and checking the results in the analysis section of the software

- The 3D model is revised and modified until all virtual analysis tests have been passed

- A finalized virtual model is prepared within the software, which then can be used to create a physical 3D model using a 3D printer, or a die of the model. If a physical 3D model is printed, it can be used as a true representation of the actual production piece in order to do final proofing before mass production; if a die is created, then a small production run will be made in order to confirm proof on concept.

- The finalized, proofed model is moved into the CAM software, where the manufacturing process takes over with parameters like feed, speed, depth of cut, stock, step-over, cutter information, cutting pattern, coolant on/off, and other instructions that will direct the machine through a step-by-step process of manufacturing.

- The CAM software virtually manufactures the model, while an engineer visualizes checks and solves problems. The engineer then verifies the manufacturing operation on the computer-generated list of instructions, and that computer-generated list becomes the CNC program.

Who Uses CAD / CAM?

CAD / CAM is advanced technology that is widely used in the field of design engineering for manufacturing technologies such as automotive, aeronautic and machine tooling; and in health technologies such as dentistry, and prosthetics. CAD / CAM technologies have also found their way into creative and artistic fields, with CAD / CAM-generated sculptures, metal art, jewelry and other artistic designs.

Why CAD / CAM is Important

CAD / CAM software and the entire CAD / CAM process enables engineers and artists alike to create more innovative concepts and more daring designs through the process of creating digital prototypes. CAD / CAM enables the performance of simulations on digital prototypes to optimize designs, a process widely used in both the automobile and aeronautic fields. CAD / CAM streamlines documentation, data management, and collaboration.

Getting Help with Your CAD / CAM Project

Often small companies and independent artists and designers are not able to take advantage of the CAD / CAM process because they lack the skill set and/or the internal personnel to operate CAD / CAM software.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...