Sheet Metal Design for Your Needs

Struggling with getting a flat pattern from a complex 3D surface? We are here to help! If your company needs help in designing solid sheet metal parts and assemblies, convert CAD models to sheet metal models – then CAD/CAM Services can be your outsourced partner.

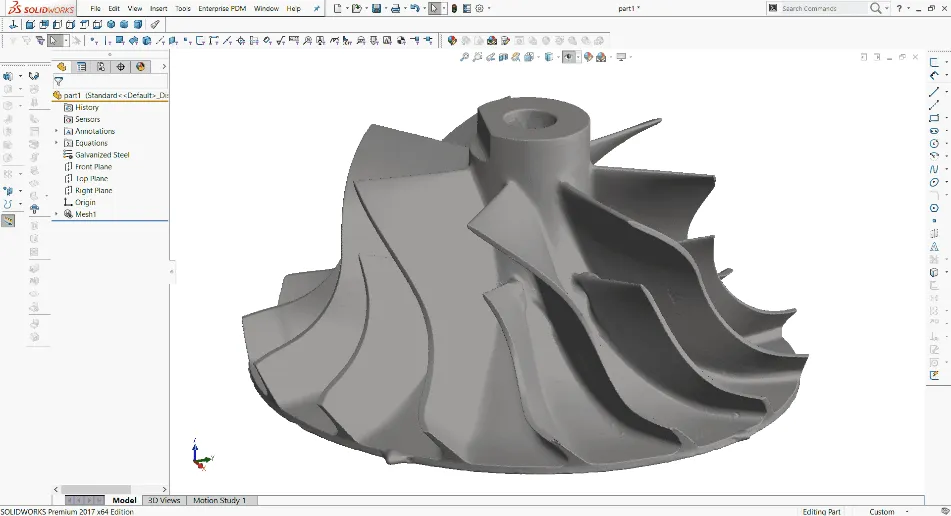

With our sheet metal service experience, you can gain the flexibility required to quickly and cost-effectively create sheet metal part designs by relying on an experienced team of sheet metal designers. We have you covered if you use CATIA, NX, Creo, Solidworks, or even Inventor.

Outsourcing to the experts at CAD /CAM will accelerate your design process, save time and development costs, and increase productivity. Good sheet metal design is a learned science, and often not for the faint of heart.

Our team of sheet metal experts can help to create sheet metal part designs using SOLIDWORKS 3D design.

Our features include:

- Flanges built to associated aerospace mold line surfaces.

- Aerospace single and twin joggles.

- Flange and joggle flattening using aerospace compensation design rules.

- Consolidated modeling environments for designing common sheet metal airframe parts.

- and consistent best practices of Sheet Metal Design.

.png)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)