Case Studies

Client

One of our clients is a US company that specializes in manufacturing vented outboard boat engine covers, and they beed to create cutsom patterns for each specific engine model.

This means that with so many different models, they have to take precise measurements of every motor in order to make a cover which would perfectly fit it.

These covers are designed for maximum protection, and should cover the upper cowling and most of the lower cowling except for the upper and lower shaft, and part of the lower cowling that is closest to the water.

Task

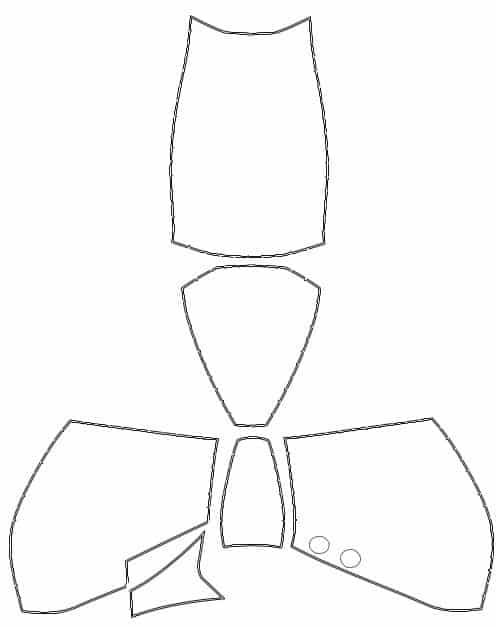

Patterns our client has produced the old way

While designing covers for the new motor models our client had to perform long and inaccurate series of measurements with hand tools in order to create a pattern which suits best.

This process sometimes involved traveling long distances between yacht clubs and workshop just to find out, that some measures were not accurate enough.

Our team had to find a solution, which would help him to reduce the number of iterations required to create new product.

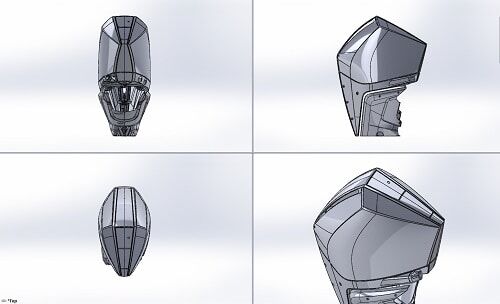

This is the original four views that were provided by the client…

Solution

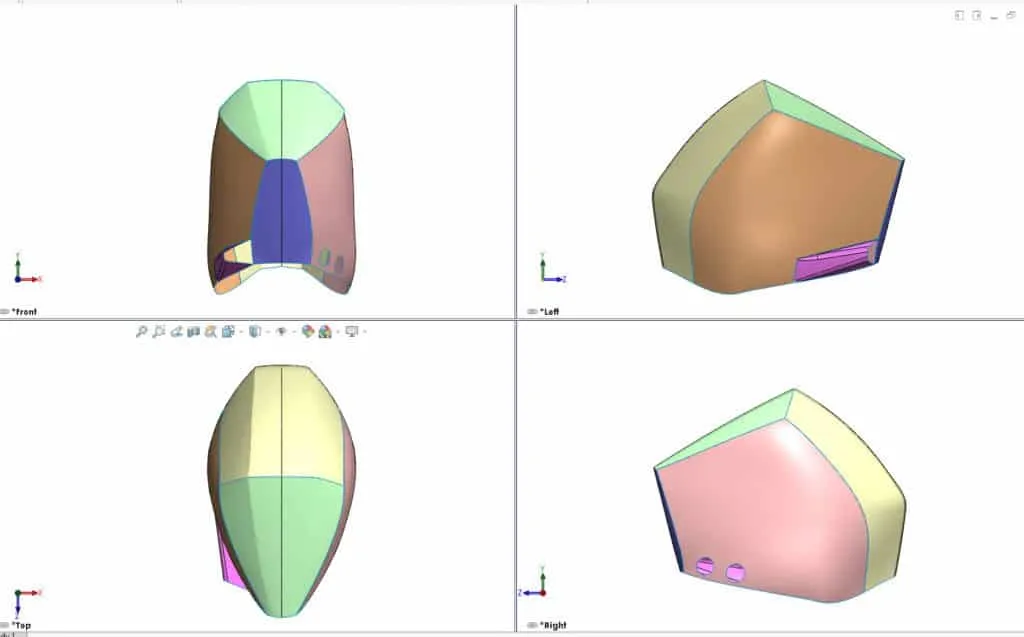

Our team used boat motor models provided by the manufacturer in STEP format. With the help of surface modeling in SolidWorks we managed to create precise patterns which later on were used to produce new makes of motor covers.

Our specialists created surfaces, which would best fit the motor. Special attention was paid to the hole placements as covers are intended to be used even while motor is running. Later these surfaces were “rolled” on a plane in order to get precise cover pattern.

Results

Covers produced with these patterns were accurate enough so that the resulting cover perfectly fit the motor. Our client was satisfied and ordered patterns for several other motors. Thanks to these patterns our client managed to drastically shorten development time for his new products and also save money on traveling expenses.

In this case, 3D model was provided by the motor manufacturer, but it is possible to apply this experience to any object even if no model is available. Our company offers 3D scanning services so if you need our help with any type of reverse engineering task, just name it!