Reverse Engineer Legacy Products | Modernize by Reverse Engineering

If you have legacy products that have little or no design documentation, let us help you document and modernize. By using 3D scanning to reverse engineer surfaces and physical parts you can bring components up to date and minimize or eliminate tool degradation. Our 3D CAD processes can provide interference checking – along with 3D model comparison to help identify and correct problems.

We begin by collecting detailed 3D data by scanning your legacy product. Then we create the appropriate CAD models to facilitate changes, corrections, and upgrades to product or tooling design. This accelerates the iterative process by which today’s products and processes are modernized and improved. We fully follow and endorse both LEAN manufacturing processes along with ISO 9000 and 9001 standards.

Our non-contact 3D Scanning process ensures that there is no damage or alteration to your product or tools in the process of collecting the data.

Modernizing by Reverse Engineering Makes Sense

Reverse engineering is a practical way to create a three-dimensional virtual model of an existing physical part. Once you have the 3D model, the use of 3-D CAD, computer- manufacturing, or other computer-aided engineering applications becomes much easier.

Reverse Engineering is a Boon for Small Companies

Small engineering companies find that reverse engineering speeds up development and cut production costs. Furthermore, when small companies outsource their reverse engineering, they benefit from up-to-date hardware and software that work together for the reverse engineering process, without the capital expense of purchase. For instance, 3D Scanners are used create a virtual digital representation of the object, which specialized software then reconstructs it as a 3-D model.

Additionally, while reverse engineering and CAD are integrated, they are two different processes, using different systems and skills. Keeping your in-house CAD team focused on your core business, eliminates the need for additional training and loss of focus from their main design responsibilities.

How it Works

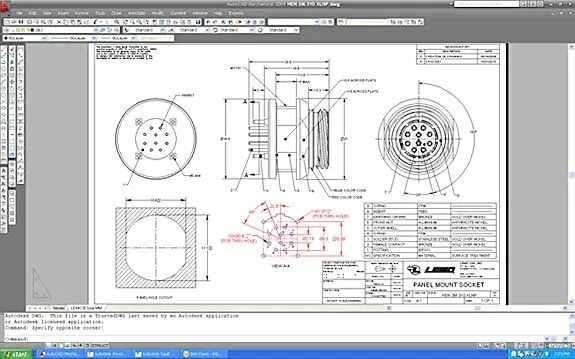

You provide us with the part you want reverse engineered. We digitize the part with 3D scanning hardware, which inputs part measurements and shapes our system. We can work with SolidWorks, CATIA, AutoCAD or nearly any other 3D software. The reverse engineered part will appear much like the originally scanned piece with appropriate improvements.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...