The Nuts and Bolts of R2V Conversion

In theory, R2V conversion is really simple. Of course, it’s one of those things that are actually more difficult than you might think. In this guide, we’ll talk about the specifics of R2V conversion — what it is, how it works, why it’s so great, and the best way to get your R2V conversion work done.

What Is a Raster Image?

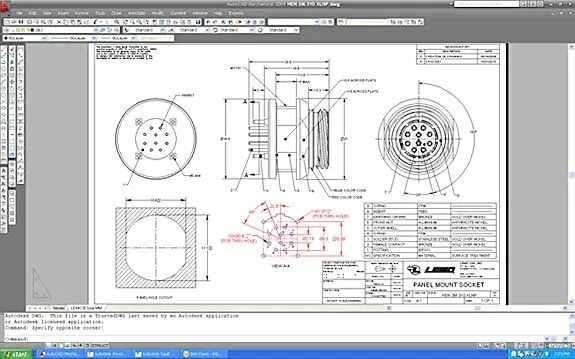

A raster image is simply a picture that’s made up of a ton of pixels, or little dots on your screen. If your raster image is a square, you won’t find any actual lines — instead, there will be countless pixels that are squished together to look like continuous lines.

Any time you’re dealing with a JPEG, BMP, TIFF, IMG, GEM, CIT, or GIF file, you’re working with a raster image. In engineering, you’ll likely experience a raster image after scanning a hand drawing or getting an image file from a vendor.

Benefits of Vector Files

As you might already know, CAD programs can’t do anything with raster images. Even though you can import a raster image into your CAD drawing, you can’t extrude the part, adjust the drawing, or change anything about the image besides its placement and scale.

If you want to get that part manufactured, then you’ll need a full vector file. In a vector file, every line has a position, distance, and length.

When you draw a square in CAD, the square has four lines with this data associated with each line, as opposed to a ton of pixels that don’t mean anything.

With a vector file, you can extrude parts, change configurations, adjust the design, and start making 2D manufacturing drawings. To put it simply, engineers need vector files in order to do their job.

This is where the idea of raster to vector, or R2V comes in. You can convert a stack of raster images into fully functional vector files through R2V conversion.

The Best R2V Conversion Strategy

First, we should mention that our team at CAD/CAM Services has done millions of R2V conversions over the past decades, so we know a thing or two about this space. Speaking from experience, there is only one viable way to convert a raster to a vector image: manually.

What do we mean by “manually”? Well, you would have to open your raster image in CAD and physically trace over the original image or create a new CAD drawing from scratch, using the raster as a reference. In either of these cases, there is no automation to speed up the process.

However, there is a way to speed up the process and save money through the process: outsourcing. The industry standard for convenient, efficient, and time-saving R2V conversion is by outsourcing the work.

In this case, you would send an outsourcing engineering firm your stack of raster images, and they’ll do all the work. Be warned, though — some companies take shortcuts and use automation that only works 50% of the time and always leads to inconsistencies and errors in drawings. If you choose the wrong company, you could get vector files that aren’t usable, and you might not notice until it’s too late.

Trust CAD/CAM Services for Your R2V Conversion

At CAD/CAM Services, we do the entire R2V conversion process manually. We have a staff of over 100 engineers and draftsmen who are experts in CAD, and they work around the clock to deliver exceptional results.

For any engineering drawings, we like to make the drawing from scratch to ensure all of the dimensions are accurate. We draw in a 1:1 scale instead of simply tracing your raster image. Why? To ensure you get the best final result.

This process takes more effort and attention to detail, but it yields better results, so it’s worth it. When you choose CAD/CAM Services, you’re getting CAD Perfect R2V conversion, no matter what.

For images and logos where dimensions don’t matter, we will likely trace over the raster image to ensure the shape is perfect. We peer-review each drawing to make sure we didn’t make any mistakes before sending them to you.

Our goal is to make sure every vector drawing you get exceeds your expectations. This must be why so many people trust CAD/CAM Services for large or small R2V conversion projects.

Conclusion

Raster to vector (R2V) conversion sounds easy on paper, but a lot can go wrong during the process. We can take your raster images and turn them into CAD-friendly vector files in no time. Trust our team at CAD/CAM Services and reach out to learn more. Get a free quote today and we’ll get started.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...