Change the Status Quo with CAD-CAM-FEA Simulation Outsourcing

Change the Status Quo with CAD-CAM-FEA Simulation Outsourcing

Historically, manufacturers have made products that have been designed with familiar materials and physically tested to ensure that the product worked properly. But, as new manufacturing materials are developed, the problem of design and test becomes more complex. The entire status quo of design and manufacturing is being upended. Options are endless and testing more complex. Unfortunately, not all design/manufacture firms are up to the task.

That’s where Simulation Outsourcing can be a boon.

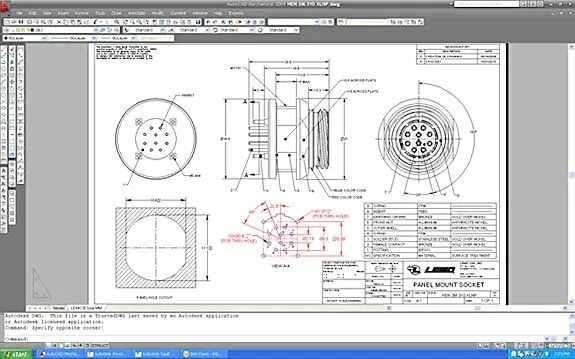

CAD / CAM (computer-aided design and computer-aided manufacturing) is standard in most organizations. Most have long ago given up pencil and paper design and have moved to computer software that is used to both design and manufacture products. CAD / CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining.

CAM software uses the models and assemblies created in CAD software to generate tool paths that drive the machines that turn the designs into physical parts. CAD / CAM software is most often used for machining of prototypes and finished parts.

Design simulation helps manufacturers verify and validate the intended function of a product under development, as well as the manufacturability of the product. There are several common design simulation approaches that have become standard and that continue to grow in importance. Design simulation software allows users to address new technologies and applications.

Simulation models are sets of mathematical equations and virtual 3D representations of the “real” product. The complexity of the simulation model varies with the complexity of the design and the material being tested to produce the product. Simulation ensures manufacturability and usability.

How Simulation Models are Used

Simulation models offer more flexibility in the product development process compared to physical prototypes. While changes in the design can be simple to make using simulation software, the problem is that using simulation software requires a learning curve not always available in a design/manufacturing environment.

Outsourced design simulation can often provide more types of analysis results that might be impossible to obtain through in-house physical testing due to lack of internal skill in a simulation. Even when the skill set is available, it is often more efficient to outsource the somewhat tedious task of testing and changing the design.

Benefits for Design/Manufacturers

Outsourced design simulation can be beneficial to both large and small manufacturers, but small manufacturers, in particular, can become more competitive by outsourcing this portion of their design process. Benefits include:

- Balancing of various functional aspects during concept development

- Evaluation of design alternatives without the trial and error of physical prototypes

- Optimizing the design by removing unneeded material, thus reducing the weight and cost while increasing design efficiency

- Providing performance and manufacturability insights earlier in the development process, when design changes are less expensive to make

- Enabling detailed, attribute-specific models that can be used for validation and product refinement

- Testing under virtual extreme conditions to prove the design concept without the expense of physical prototypes.

Outsourced simulation testing can also enable the testing of products that cannot be physically accessed with measurement equipment, an output physical magnitudes for which no sensors exist, and provide a virtual view into the factory floor to understand manufacturing processes.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...