3D Scanning for Engineering | 3D Scanning Service | 3D Scanning for CNC

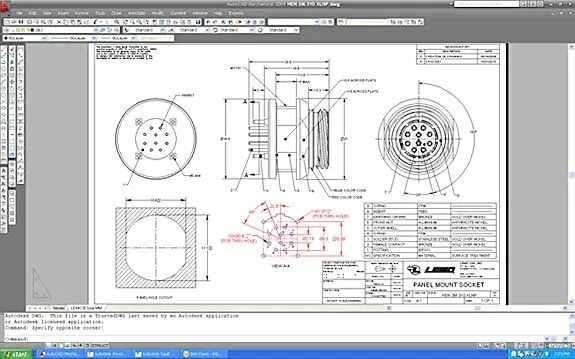

When you need a fast and accurate method of putting physical measurements of an object into your CAD system, CAD / CAM Services provides expert 3D scanning. The 3D scanned data can be represented by a scale digital model or a 3D graphic rendering. The scanned data provides all of the physical dimensions of the object, such as length, width, height, volume, feature size, feature location, and surface area.This 3D scanned data acts as a bridge between the actual physical object and manufacturing. The data from the 3D scan can be converted into CAD / CAM data used by CNC machines. Our 3D scanning service is invaluable for CAD modeling, reverse engineering, contact/non-contact dimensional inspection, and ISO 17025-accredited integrated metrology services and saves many hours of grueling redesign work by your engineers.Even the movie and entertainment industry makes use of 3D scanning to create animated versions of real physical objects.However, most of our customers are in manufacturing, engineering and military environments. The ability to reverse engineer nearly any object makes it possible to create and do things that previously were impossible. Not only has 3D scanning created possibilities, it has also created opportunities because the technology we use is both mobile and adaptable to many different scenarios.We can even perform on-site 3D scanning that provides incredible accuracy at prices that offer a far better ROI than having your staff reverse engineer an object by hand.

Basic 3D Scanning Service

Small objects to entire rooms can be scanned using a powerful 3D real-time scanning system. The system makes use of specialized sensors to gather data, regardless of the object’s shape or size. The data is captured from 3 & 4 axis creating multiple angles and converted into a 360 degree 3D mesh, which is automatically and perfectly aligned, because of we smooth that data. We can even combine and finalize meshes with different customizable settings to help you get the results that you need. Finally, we edit, process and export the data for you to use with your own 3D modeling software, such as SolidWorks, Revit, CATIA or we can create the 3D model or render for you.

Advanced 3D Scanning Services

There are many different methods for capturing the 3D measurements of a physical part and thus, many different types of scanners. For more advanced requirements, we also offer to scan with a high-accuracy white light technology that enables capturing digital 3D scans from physical objects in mere seconds. Using a pair of machine vision cameras, the scanner captures a single scan at up to 0.0018″ accuracy and generates up to 2.6 million points per scan. Because scanning is done with no physical contact, there is no measurement interference for true non-destructive reverse engineering and testing. We interpolate the dense point cloud captured by our structured light scanner into highly accurate 3D CAD models that can be confidently used for reverse engineering when the highest accuracy possible is essential (for instance in aerospace and military applications sensitive manufacturing operations and metrology applications.)

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...