How 3D Scanning Services Can Save Engineering Teams Money

So many engineering projects revolve around the timeline, budget, implementation costs, and avoiding human error. Did you know that most of these issues can be dealt with by leaning on 3D scanning services?

In this guide, we’ll explain what these services do. More specifically, we’ll outline how 3D scanning services can save your engineering team money and protect your timeline.

What Are 3D Scanning Services?

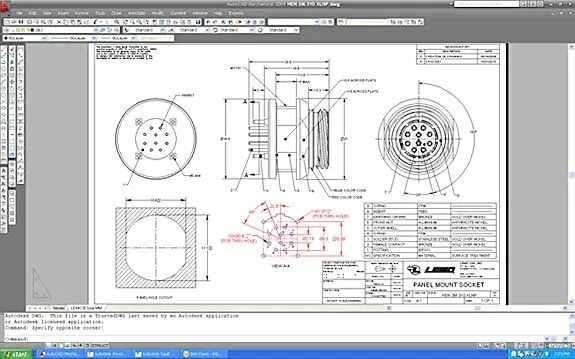

A 3D scanning service is when a third-party company comes out with high-tech laser scanners. They use the laser scanners to get a full 3D map of your product, building, or process. This map will get converted directly to 3D CAD software as a model that you can move around and interact with.

Let’s say you get a 3D scan of a screwdriver. You can use the scanned model to change the head, widen the base, and add features on the screwdriver.

People choose 3D scanning services for a number of reasons. The bottom line is that this service can save you a lot of money, which we’ll discuss later.

Some companies decide to buy their own 3D scanner, but it’s not always the best idea. For one, they’re incredibly expensive. If you’re not 3D scanning things often, then this is just wasted money that will sit in a drawer somewhere.

In addition, 3D scanning isn’t as easy as it might seem. Simply pointing the scanner at your object and hoping for the best can lead to unreliable models and wasted time — you need a certain level of expertise to execute professional-grade 3D scans.

On top of that, it’s a time commitment to learn how to successfully 3D scan a part.

Instead, you can turn to a third-party solution. In this case, a company like CAD/CAM Services will come to your site and perform the full 3D scan. We’ll walk through your operation, scanning whatever parts are required. Afterwards, we’ll go back to our home office and compile the scans into a comprehensive 3D CAD model and share it with you.

You’ll get solid parts in the model that are incredibly accurate and are representative of what you have on the floor.

How 3D Scanning Services Can Save Engineering Teams Money

To better understand how 3D scanning fits into your engineering team, consider the following benefits. These are all linked to saving money for any engineering team, regardless of the application or industry.

Faster Product Development

Often, the biggest time sink in product development is getting accurate models of mating interfaces and assemblies. For your new product to fit, you need to accurately map the current parts.

To grab these measurements, you need to use calipers or laser measurers to get dimension, jot down the dimensions, then go back to your computer and map it using CAD.

As you probably know, this takes a long time. If you forget a dimension, you need to go back to the product and do it all over again.

Or, you could use a 3D scanning service. Our scan would map out the part perfectly, and you’ll be left with a usable 3D model.

From there, you can measure the different features or start on your new 3D model and insert it into the existing process line.

Expedite Reverse Engineering

Reverse engineering is a huge part of most operations. It might be a vendor component that you can’t get original drawings for, an undocumented part from your company’s past, or a part that you need to update and integrate.

Regardless of why you need to reverse engineer the part, 3D scanning can be a big help. We’ve had customers ask us to 3D scan a part so they could immediately 3D print it and create a quick spare.

Our 3D scanning service will digitize the part and create a digital twin. In a matter of minutes or hours, you’ll have a fully functional, dimensionally accurate, digital version of the part you’re holding in your hand.

To do the same operation with calipers could take days, depending on the complexity of the part. This is a lot of wasted engineering hours.

Free Up Your Engineers

Speaking of wasted engineering hours, isn’t there something better your team could be doing besides manually measuring a machine? We’ve talked to companies that spent hundreds of hours digitally mapping their equipment, parts, and operation. That’s over a hundred thousand dollars wasted.

Instead, the same company could get even better results with 3D scanning services. The best part? It would take a handful of hours, instead of hundreds.

With this extra time, your engineers can focus on research and development, coming up with the next product, or optimizing your current catalog. The bottom line is that choosing CAD/CAM Services’ 3D scanning services frees up your engineers to do other work.

Remove Human Error

A lot of engineering work is hinging on human error and avoiding potential issues. Something as simple as incorrectly measuring a part could lead to huge problems down the line. Even simpler, what if someone misreads the tape measure, writes down the wrong number, or inputs the wrong dimension in CAD? These tiny mistakes can result in a part that simply doesn’t work.

The problem is that you might not notice the mistake until the manufacturer made it and it’s sitting in your shipping bay. At that point, it’s way too late.

How can you avoid these issues? Turn to technology and automation. When we use our 3D scanners, there is very little room for human error. Even if there’s a mistake during the scanning process, it would be immediately noticed before sending you the drawing file.

Catching these mistakes earlier and avoiding most of the human error improves your confidence in every model. It helps you avoid timeline-disrupting, budget-blowing, headache-causing mistakes.

Gain a Trusted 3D Scanning Partner Today

A good 3D scanning company will be your partner. Ideally, you should trust this company and even allow them to do some engineering work. With the right 3D scanning company in your corner, your projects will be easier to implement.

Conclusion

Having a 3D scan of your operation, part, or machine can save you a ton of money. Your engineers can move to other projects, and you can save countless hours.

For the best results, consider CAD/CAM Services. We handle 3D scanning, engineering, drafting, and designing. Our goal is to make engineering as easy as possible for you. Reach out today for a free quote.

Recent Posts

CAD Outsourcing Doesn’t Have to Be Done In India

CAD Outsourcing Doesn’t Have to Be Done in India Do a Google search for “CAD Outsourcing” and what you’ll find is lots of firms located in India, which is fine if you’re prepared to go off-shore for CAD services. But what if your U.S. based company prefers to stay a...

AutoCAD Fiber Optic Designs & Drawings

Before proceeding forward in explaining the affinity between AutoCAD and Fiber Optic, it would be prudent to rationalize the utility of optical cables. When communicating between systems, either via the internet or via an internal network system, a medium needs to be...

CAD Outsourcing: How to Get the Most Out of Engineering

In today’s competitive market, companies need as much help as possible. If you want to take a larger market share, you can start by outsourcing some of your work. This is a quick way to expand your engineering power without onboarding and training a new staff. This...